- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

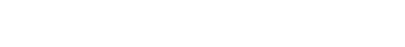

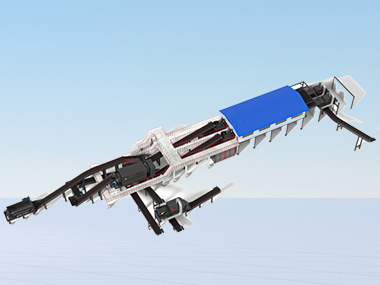

FYK Series Flip-Flow Screen

Processing Capacity:30-750m³/h

Feed Particle Size:0-400mm

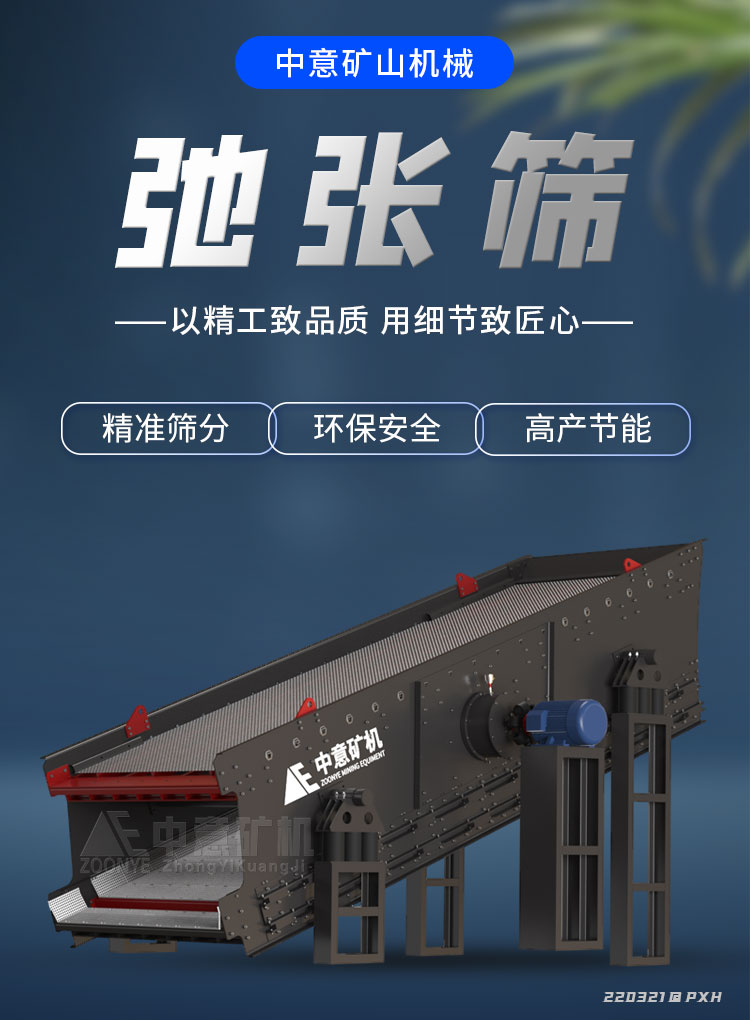

Applicable Materials:Used for medium and fine-grained, sticky and bulk materials

Application Scope:Construction solid waste recycling, mining, metallurgy, coal, building materials, chemical industry and other industries

- +8613503852957

- 7 * 24-hour Service Hotline

Flip-Flow?screen manufacturers

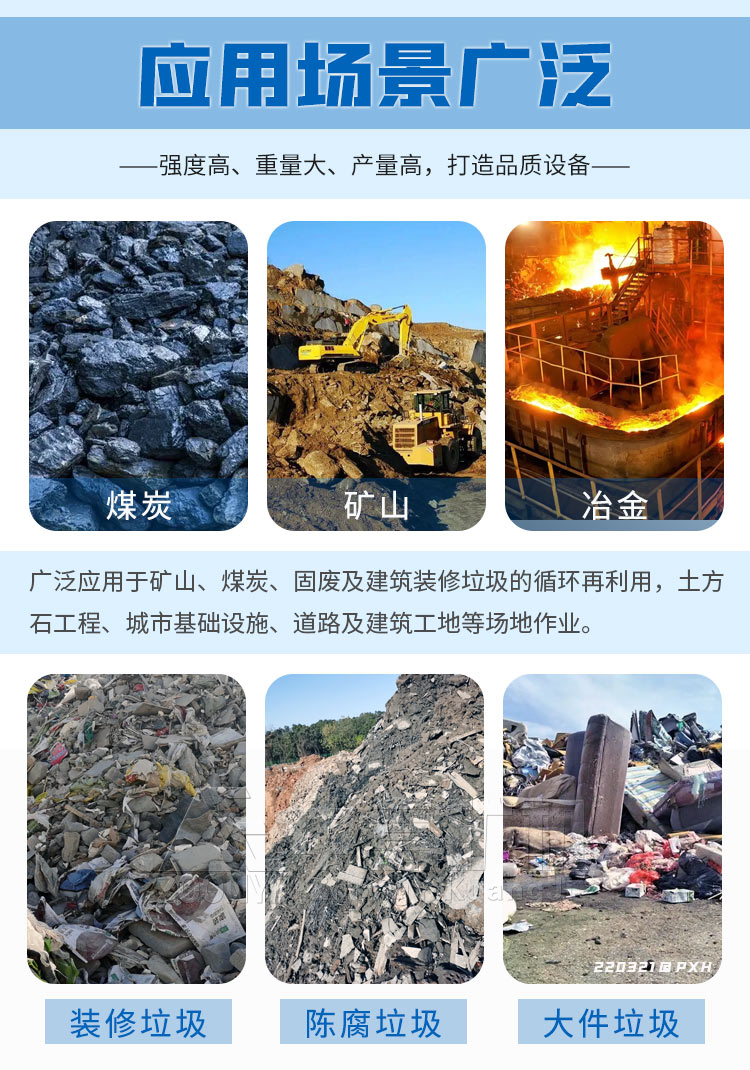

The Flip-Flow screen is a new type of screening machinery produced by our factory, which can screen construction and decoration waste, coal and other sticky materials. This machine uses a vibrator to provide exciting force for the screen machine, and the screening machine throws materials through the Flip-Flow and tension motion of the elastic screen surface installed on the tilted screen box. Its main features are improved screening efficiency, large processing capacity, small dynamic load, low power consumption and low noise, so it is widely used. During this process, the elastic polyurethane screen surface continuously expands and contracts at a frequency of 800 times per minute, effectively preventing the screen holes from clogging.

Flip-Flow screen suitable materials

Screen material 0-10mm

Upper screen material 10-40mm

Screen surface when screening decoration waste

Advantages And Characteristics

Product advantages of Flip-Flow screen

1. Since the Flip-Flow?movement of the screen surface can transmit acceleration to the materials, it can screen difficult-to-screen materials and the screen holes are not easily blocked.

2. The material speed at the feeding end is fast, the material layer is thin, a large amount of materials can be screened, and the processing capacity is high. The screen surface at the discharge end has a low inclination angle and the material speed is slow, which allows the remaining undersize materials to be thoroughly screened to achieve very high screening efficiency.

3. The linear motion box-type vibrator has high reliability and simple maintenance.

4. The polyurethane screen plate of the Flip-Flow?screen is specially designed to withstand a vibration intensity of 50g and 800 flexures per minute. The screen plate has a long service life. The screen machine is located on a hollow rubber spring, which produces low noise and Rubber springs have a long life.

5. The "U" shape design on the side of the screening machine forms a seal. The side plates have no wear and prevent the objects above the screen from entering under the screen. The screen plate is fixed with wedge-shaped rubber strips without any bolts. It is easy and fast to disassemble and assemble. The extension machine has fewer rotating parts, high operational reliability, less daily maintenance workload, high utilization rate, and adjustable Flip-Flow?screen with floating screen frame amplitude.

Working Principle

Working principle of Flip-Flow screen

The Flip-Flow screenis a dual-mass vibration system that uses a polyurethane screen surface. Any two adjacent beams supporting the screen surface belong to two vibrating mass bodies, one of which is the screen box and the other is the counterweight. When working, the screen mesh alternately tightens and relaxes, causing the material to bounce forward, which can prevent the material from adhering to the screen mesh and blocking the screen holes. When the two masses vibrate with two phases out of phase, any two adjacent beams sometimes approach and sometimes move away from each other, and the elastic screen surface also relaxes and tightens accordingly. That is, the screen surface moves along with the screen box and is also relative to the screen box. make relative motion. This relaxation movement not only causes the screen holes to continuously deform, but also greatly increases the vibration intensity of the screen surface, thereby effectively overcoming the clogging of the screen holes and significantly improving the processing capacity of the screen machine. However, because the vibration intensity of the screen box is not large, the mechanical strength is easy to ensure, but the vibration intensity of the screen surface is large and it is repeatedly deformed, so the life of the screen surface is low.

Technical Parameter

| Model | Power(kw) | Throughput(m3/h) |

| FYK1860-2P-B | 22 | 30-200 |

| FYK2160-2P-B | 30 | 45-350 |

| FYK2460-2P-B | 37 | 60-380 |

| FYK3280-2P-B | 45 | 80-750 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)